With the appointment of Zyran Scharf as full-time Sustainability Manager in 2020, NZ Panels Group has been on a mission to reduce its environmental footprint.

The aim is to become carbon negative, says Zyran, and reducing energy consumption is a big help while renewable sources of energy are investigated.

“The energy project is just one of a myriad of sustainability projects currently underway and we’re also excited to be working on a number of ‘give back’ environmental projects that will be announced in the coming months.

“We have stepped up our initiatives to reduce waste and increase recycling, with the goal of ultimately having no waste going to landfill.”

One of the foundation projects has been an energy audit supported by EECA that identified changes to lighting and improvements to energy efficiency estimated to save more than 200,000 kg of carbon emissions a year.

The audit covered two of the company’s three sites – the Kopine particleboard plant at Kopu and the Eastfield site in Auckland which has two melamine presses and a veneer press. The findings were then translated to the Nelson melamine plant.

Changes now complete include the replacement of the main highbay factory lights with more modern, energy-efficient, LED sensor lights which dim or turn off when enough natural light comes in through skylights or no motion is detected. It’s estimated this will save around 47,000 kg of CO2 each year.

Sensors were also added into the temperature-controlled melamine paper room – not only does this save power on lights but also the air conditioning with far less heat is being generated from the lights.

Insulation is another area that is estimated to save around 160,000 kg of Co2 each year. Fibreglass blanket wraps have been added around each of the melamine presses (two in Auckland and two in Nelson) along with the veneer press in Auckland. This will soon include the particleboard production line and veneer dryer at Kopu. This has resulted in a reduction of heat loss and subsequently lower energy consumption to run.

Prime Panels has launched a new hand-crafted veneer range that emulates the look of solid timber but uses around 20 times less resource than solid timber would.

The Prime Toitū range uses mis-matched leaves in a stunning planked effect and includes six NZ Native timber options along with American White Oak, Macrocarpa and American Walnut. Click to view the whole range.

The name Toitū was chosen to represent the sustainability inherent in these mis-matched veneer panels and the fact that two-thirds of the species offered are homegrown. One cubic metre of solid timber yields 900 square metres of veneer and with no need for matching leaves or panels, the irregularities, knots and beauty of natural timber are brought to the forefront.

The best effect is achieved on large-scale cabinetry and for wall and ceiling panels where the look of solid timber is desired, but with more sustainability and affordability than solid timber.

The added advantage of using NZ Native Toitū veneer is the ability to track back to the trees they came from with NZ Panels Group's world-leading Track my Tree initiative.

NZ Panels Group is proud to be one of six companies short-listed for the 2021 Sustainable Business Awards - Communicating for Impact category.

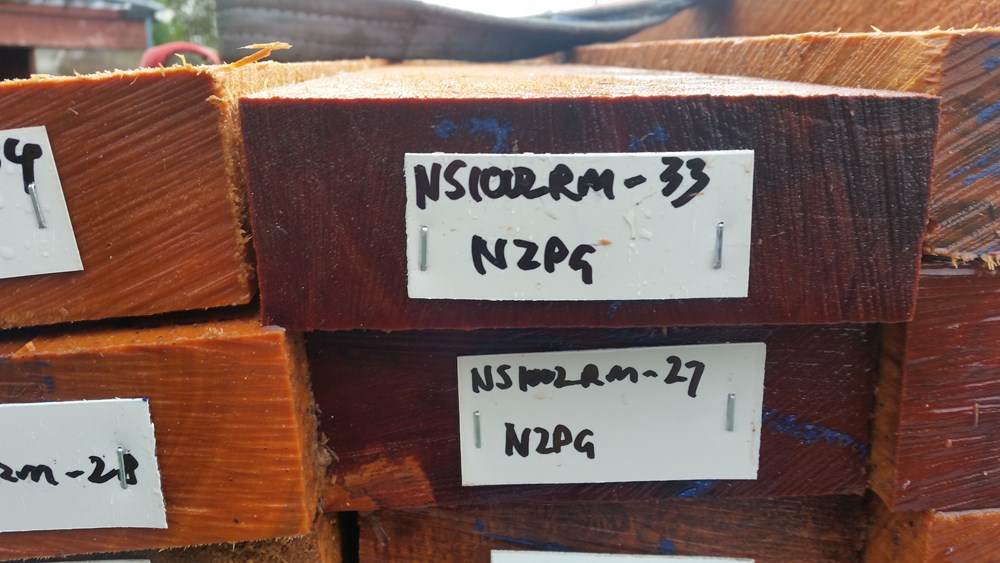

The Track my Tree initiative offered under Prime Panels and Bestwood is a unique program that offers complete transparency over NZ Native Veneer panels from the tree to the veneer press at NZ Panels manufacturing site in Auckland.

If you have a Track my Tree code for your NZ native veneer panels from Prime Panels or Bestwood, you can be confident there is a documented chain of custody from the source right through to our veneer press in Auckland. This also includes a valid MPI permit for harvesting and GPS location information.

The Track my Tree code is printed on the invoice when a native veneer species is sold to a merchant or joiner. It also appears as a printed code attached to the side of the veneer panel when it leaves our plant. It means you can trace the tree (or group of trees) that your veneer panel came from. By entering the code into the Track my Tree database on the Natural Veneer page of our website, you can:

- View the location of the tree (or trees) on Google Earth

- View the MPI permit that shows your veneer was sustainably sourced

- See the source type of your tree i.e. windblown

Even if you haven’t bought our veneer, or don’t have a code, you can still use the search feature to browse through all the New Zealand native trees we have tracked – filtering your search by species type.

Prime Panels, Dezignatek and Bestwood products featured heavily among the winning entries in the recent NKBA Excellence in Design Awards.

Taking out the Supreme Award for both the Bathroom and Kitchen categories, Davinia Sutton of Detail by Davinia featured Prime Art Sawn Veneer in both projects, along with three other projects from her design studio that picked up awards on the night.

Dezignatek and Bestwood also featured with a mix of thermoform, veneer and melamine included in winning projects.

Visit the showcase page of each of our websites to view these stunning kitchen and bathroom projects:

NZ Panels Group has opened a new showroom within the Home Ideas Centre in Parnell, Auckland. It replaces the showroom at the company's East Tamaki manufacturing site which is now closed.

Designed primarily for architects and designers, the showroom features large format surfaces from Prime Panels, Bestwood and Dezignatek. New technology and imagery give visitors an inspiring view of how these surfaces can be used in both residential and commercial projects.

The concept design was developed by Spaceworks with Retail Dimension carrying out the detailed drawings and construction. Take a 3D virtual tour through our showroom here.

Key features within the showroom include:

- A dynamic wall that shows off the most popular melamine and laminate designs in large format.

- QR codes on all surfaces that take you directly to the swatch on our website so samples can be ordered.

- An island benchtop in Prime Stone Statuario Venato leather finish which combines with a Recon veneer table workspace.

- Stone drawers underneath the benchtop that feature the entire Elements and Babylon Collection in large format. A styling wall with stunning mood boards and installation shots.

- A veneer space showing off NZ native veneers and Track my Tree QR codes which can be scanned to view the actual tree and location the veneer panel came from.

- A wall of four different finishes for American White Oak including Prime Art Veneer planked, and in a rustic, sawn finish.

- A tablet allowing users to access a 'mini website' to browse ranges, view videos and order samples.

The Auckland-based specification team will be working out of the showroom by appointment with designers and architects.